- Description

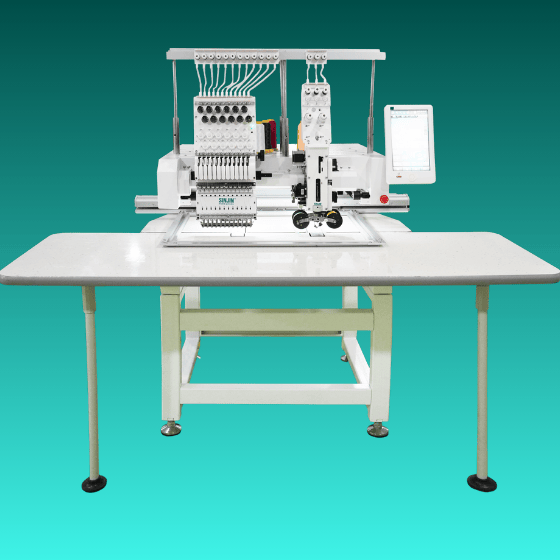

- Machine Specifications

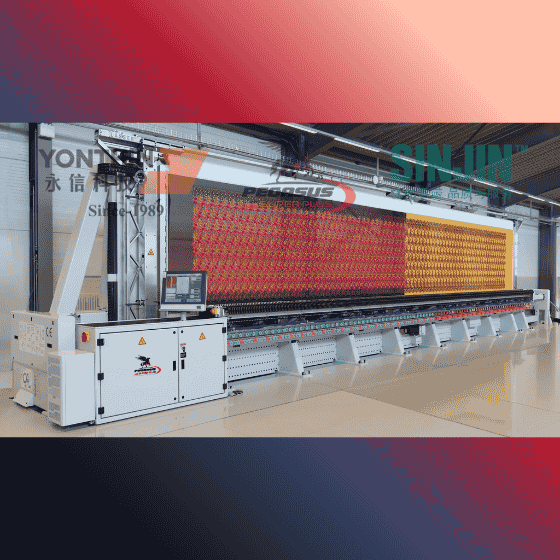

Product Description

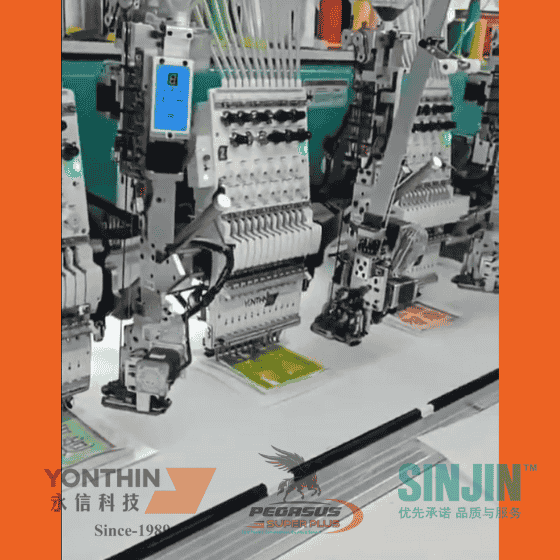

Multi head cap embroidery machine

YONTHIN fashion custom intelligent special type embroidery machine:Ready-made cloths、trousers、hats、shoes、jackets、bags、cutting picese can be switched and embroideryed at will.

● Advanced equipment support

● Advanced production technology

● High standard quality control

● Easy and convenient operation

● Multiple optional devices

● Expansive embroidery area

● High working speed

● Can customize various models

Basic info

CE

Certification

Custom

Needle Number

Multifunctional

Key Selling Points

Dahao Servo Motor

Motor

New

Condition

Automatic

Automatic Grade

Machine Specifications

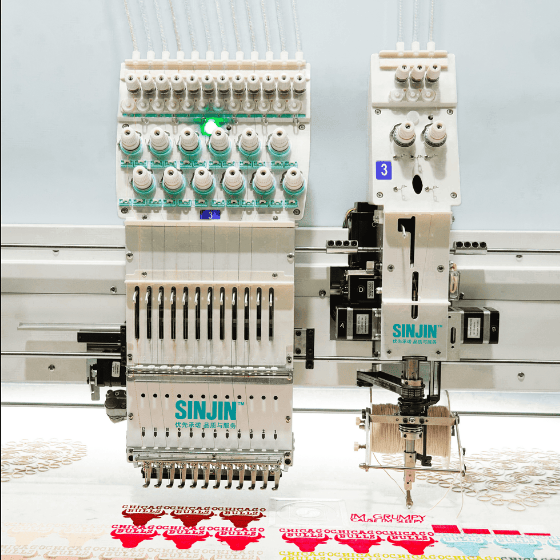

| Advanced Equipment Support | Built with high-precision servo motors, upgraded electronic control boards, intelligent sensors, and stable drive systems for reliable, consistent embroidery performance. | Advanced Production Technology | Manufactured using CNC machining, automated assembly, strict process standards, and cutting-edge engineering to ensure accuracy and durability. |

| High Standard Quality Control | Every machine passes multi-stage inspections including stitch accuracy tests, vibration tests, endurance testing, and final quality certification before delivery. | Easy & Convenient Operation | User-friendly touchscreen interface, real-time monitoring, quick design adjustment, automatic thread trimming, and simplified maintenance functions. |

| Multiple Optional Devices | Supports cap embroidery device, sequin device, cording/taping device, laser alignment system, WiFi networking, and auto-lubrication options. | Expansive Embroidery Area | Offers large working area options such as 400×450mm, 500×700mm, 600×900mm, and fully customizable large-format sizes for industrial production. |

| High Working Speed | High-speed embroidery range 850–1200 RPM, ensuring smooth stitching, low noise, and high output efficiency. | Can Customize Various Models | Available in 1–15 head configurations, 6/9/12/15-needle versions, multiple frame sizes, and custom specifications tailored to production needs. |

| Thread Trimming | Automatic Trimming | Advantage | High Efficiency Automatic Working |

| Embroidery Type | Towel Embroidery, Patch Embroidery, Clothing Embroidery, Hat Embroidery, Flat Embroidery, Custom | Language | 19 Languages |

| Optional Devices | Sequin+Cording+Chenille |

| Advanced Equipment Support | Built with high-precision servo motors, upgraded electronic control boards, intelligent sensors, and stable drive systems for reliable, consistent embroidery performance. |

| Advanced Production Technology | Manufactured using CNC machining, automated assembly, strict process standards, and cutting-edge engineering to ensure accuracy and durability. |

| High Standard Quality Control | Every machine passes multi-stage inspections including stitch accuracy tests, vibration tests, endurance testing, and final quality certification before delivery. |

| Easy & Convenient Operation | User-friendly touchscreen interface, real-time monitoring, quick design adjustment, automatic thread trimming, and simplified maintenance functions. |

| Multiple Optional Devices | Supports cap embroidery device, sequin device, cording/taping device, laser alignment system, WiFi networking, and auto-lubrication options. |

| Expansive Embroidery Area | Offers large working area options such as 400×450mm, 500×700mm, 600×900mm, and fully customizable large-format sizes for industrial production. |

| High Working Speed | High-speed embroidery range 850–1200 RPM, ensuring smooth stitching, low noise, and high output efficiency. |

| Can Customize Various Models | Available in 1–15 head configurations, 6/9/12/15-needle versions, multiple frame sizes, and custom specifications tailored to production needs. |

| Thread Trimming | Automatic Trimming |

| Advantage | High Efficiency Automatic Working |

| Embroidery Type | Towel Embroidery, Patch Embroidery, Clothing Embroidery, Hat Embroidery, Flat Embroidery, Custom |

| Language | 19 Languages |

| Optional Devices | Sequin+Cording+Chenille |